Modular Crane Manufacturing Company

Assure your success with

our products & support

Electric Wire Rope Hoists

Wire Rope Hoists are designed & requirements of IS: 3938. Few salient features of the hoists are easy of use & maintenance, better Headroom, Modular construction.

| Features | Description |

|---|---|

| Rope Drum | Fabricated from Seamless Pipes with grooves for proper seating of wire rope. |

| Frame | Fabricated from plates confirming to IS: 2062, Gr A, laser cut profile & duly finished in boring machine. |

| Gears & Pinions | Helical type, made from Alloy steel materials, duly hardened and tempered. Teeth cutting carried out after heat-treatment for smooth, less noise operation. |

| Bearings | Heavy duty ball bearings of reputed makes used on all rotating parts, grease packed. |

| Motors | S4, 150 Starts per hour, 40% CDF, crane duty Squirrel Cage motors as per IS: 325 |

| Wire rope | As per IS: 2266 of reputed make suitable construction, factor of safety as recommended in IS: 3938. |

| Rope guide | Provided for guiding the rope along the axis of Rope slides & is easy to dismantle from rope drum. |

| Hook | Forged steel as per IS: 3815 supported on thrust bearing. Hooks as per IS: 15560 shall be offered on request. |

| Brakes | ACEM Disc brake provided for hoist and for Cross Traverse shall be provided on request. |

| Limit Switch | Normal roller type limit switch provided for over-hoisting & over-lowering. |

| Trolley Adjustment | Trolley easily adjustable for different beam sizes. Higher flange width shall be offered on request. |

PRODUCT DESCRIPTION

- CT Brake and CT Limit Switch

- Panel for LT Drive

- VFD for hoisting and cross traverse motion

- Higher height of lifts

- Different speeds for hoist and CT

- Power supply systems

- Shoe brake

- Manual geared trolley, flexible trol curvature, push-pull trolley

| S.W.L Kgs. |

Height of Lift in Mts. |

No. of Falls |

Speeds Mpm | Motor H.P | Flange Width of I Beam |

Wire Rope Dia |

Dimension(m.m.) | Approx WT. in Kgs. |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hoisting | CT | Hoisting | CT | A(HR) | B | C | D | H | I | ||||||

| 500 | 6 | 2 | 3.5 | 12 | 0.75 | 0.25 | 90-150 | 6 | 600 | 175 | 500 | 700 | 275 | 375 | 150 |

| 1000 | 6 | 2 | 3.5 | 12 | 1.5 | 0.50 | 90-150 | 8 | 650 | 175 | 500 | 850 | 275 | 375 | 170 |

| 2000 | 6 | 2 | 3.5 | 12 | 3.0 | 0.50 | 100-180 | 10 | 800 | 200 | 550 | 980 | 310 | 400 | 400 |

| 3000 | 6 | 2 | 3.5 | 12 | 5.0 | 0.50 | 125-180 | 10 | 850 | 225 | 600 | 1150 | 350 | 450 | 450 |

| 5000 | 6 | 2 | 3.5 | 12 | 5.0 | 0.50 | 140-400 | 10* | 1000 | 225 | 750 | 1250 | 450 | 450 | 550 |

| 7500 | 6 | 2 | 3.5 | 12 | 7.5 | 0.75 | 150-400 | 12* | 1200 | 225 | 850 | 1700 | 525 | 500 | 1000 |

| 10000 | 6 | 2 | 3.5 | 12 | 10 | 0.75 | 150-400 | 14* | 1300 | 225 | 850 | 1700 | 525 | 500 | 1200 |

| 15000 | 6 | 2 | 2.5 | 12 | 12.5 | 1.0 | 180-400 | 14* | 1600 | 300 | 1250 | 1850 | 650 | 600 | 1600 |

| 20000 | 6 | 2 | 2.5 | 12 | 15 | 1.0 | 180-400 | 18 | 1800 | 325 | 1250 | 1850 | 650 | 600 | 2200 |

Single Girder Overhead Cranes

The single girder overhead crane is our flexible crane for almost any application. Even in buildings with low ceilings effective material flow solutions can be achieved for loads of up to 16 t and spans of up to 39 m. Normally safety clearances below ceilings are not required for single girder cranes within this load range. This allows the optimal use of existing space or can save additional building height costs.

The single girder overhead cranes adapt to different building applications due to their various main girder connection variants. Favourable crane dimensions help to reach optimal highest hook positions. The main girder connection is the optimal solution for new factory buildings as this version offers the best side approach dimensions. If lifting height is the decisive factor then a single girder crane ELS with side-running trolley is the right choice.

The single-girder travelling crane is also a good choice for special solutions: The accessories and components offer specialised additional equipment to satisfy your requirements.

Robust rolled section girders form the crane girder of the single girder overhead crane ELV whereas single girder overhead cranes ELK and ELS consist of torsion resistant welded box girders.

Capacity 1 UP t0 15000 kgs.

Span : Up to 30 mtrs.

Long travel speed : UP to 30 mtrs /min.

Cross travel speed : Up to 15 mtrs /min.

- Suitable for short headroom.

- Small capacity types with shanter span.

- Frequency use for loading and unloading works.

- Its simple construction reduces the moderate cost.

Slung Suspension Type Single Gir...

The next option is the under-slung crane, which runs on the bottom flanges of rolled steel beams which form the crane tracks. These are usually indoor cranes and the crane tracks are suspended from the building structure. They have the advantage of being able to cover part of the building span without obstructing the floor below. Latest in this type are light weight crane systems wherein hollow sections are used as track sections inside which the travel trolley wheels move. These track sections can be used for the long travel tracks and also for the crane bridge. The under-slung arrangement allows the bridge of this type of crane to be designed with a cantilever at one or both ends.

These under slung/Suspension Cranes are used in the areas where there is no option of the supporting steelwork beneath the floor. The track for such cranes is held by the roof structure or by the pillars. These cranes required less space and run on the lower flange of the crane runway. This flange is placed directly on the ceiling and is highly profitable in terms of judicious use of space. We manufacture these in compliance with the requisite industry standards.

Capacity : Up to 10 ton.

Span : Up to 20 mtrs.

Long level speed 5 UP to 20 mtrs / mm.

Cross trave: Speed 1 UP to 15 mtrs /m

- Used when ceiling height of relatively small.

- Run under I beam which is fixed under ceiling.

- Totally used on shop floor area without any obstruction.

- Cost effective.

- Best solution for longer span.

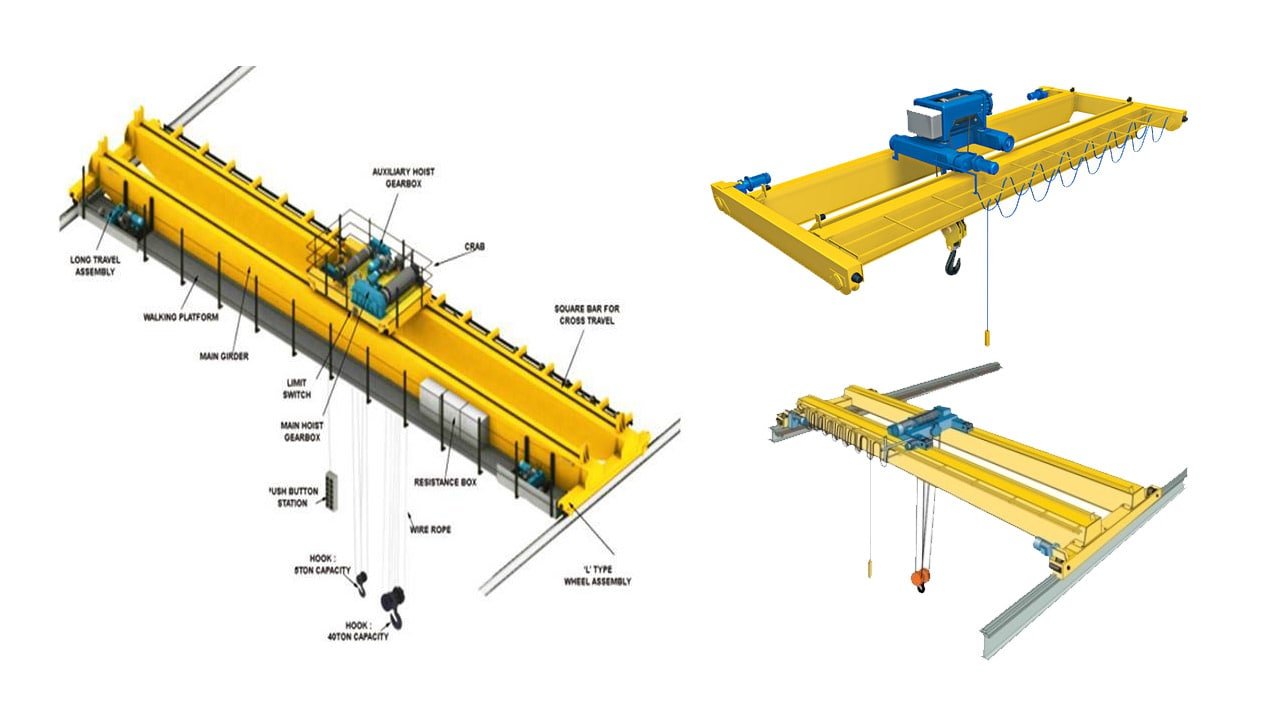

Double Girder Overhead Cranes

The main structure of crane is composed of box steel two beams or profiled ones coupling with travelling motorized carriages. The lifting system consists in winch or hoist in accordance to the requirements which runs on beams allowing horizontal movements.

TOP RUNNING / DOUBLE GIRDER OVERHEAD CRANE

Capacity : Up to 100 ton

Span : Up to 30 mtrs

Long travel speed : Up to 40 mtrs / min

Cross travel speed : Up to 20 mtrs / min

- Used for large capacity with large span

- Suitable for large headroom

- Used for high frequency is any motions

L.T. WHEELS

The wheel of the trolley and the end carriages shall be forged steel conforming to IS 2707, GR II, Duly spin hardened to 300 BHN. Materials, double flange straight thread type fitted with antifriction bearings mounted on 'L' type bearing housing assembly for the ease of the maintenance.

CONTROL PANEL

- Latest crane control solution - AC variable speed drives.

- Control torque.

- Allow accurate positioning.

- Different operating speed control.

- Smoother operation.

- Reduces the stress on electrical equipment.

- Eliminate micro speed motor, micro gear box & additional brake.

- Directly save on equipment cost with better performance.

- Eliminates the need for magnetic reversing contactors.

- Reduces the wearable components in panel.

- Reduces long term maintenance cost.

Double Girder E.O.T Cranes (Modu...

We are a world-class supplier of overhead cranes and various types of material handling equipments to customers located in India and abroad. We have been celebrated as a name equivalent to high quality, innovation and reliability in almost all kinds of material handling applications and environments. Our range of offerings include Hydraulic Equipment, Goods Lifts, Hydraulic Pallet Trucks, Material Handling Equipment, Hand Pallet Truck, Double Girder Crane, EOT Cranes Gantry Cranes, Panel Board Accessories and we also manufacture crane spare parts.

We have grown rapidly from a fledgling concern to a giant material handling equipments manufacturer in a matter of a few years. This has been made possible by our focus on customer satisfaction and quality. Our prime focus is on manufacture of products of the highest quality standards. Our processes are backed by strict quality controls and process controls at each stage.

Capacity : Up to 100MT

Span : Up to 40 mtrs.

Class of duty : Upto Class IV (M8), Extra Heavy Duty

Design Standard : IS : 3177 / IS :4137 / IS : 807

- Class IV, ExtraHeavy Duty Ladle Handling, Coil Handling, Scrap Handling with magnet, Billet Handling etc. cranes for the Steel Industry

- Multiple trolley cranes with individual & tandem operations for Power Industry

- Specialized precision control cranes for Turbine Handling for Power Industry

- Cane Uploaders for Sugar Industry

- Flame proof cranes for refineries

- General Purpose E.O.T Cranes

- Specialized Low Head Room Cranes

- Under Slung Cranes

- Grabbing Crane for Sugar Industries with high speed.

Grabbing Cranes

Grabbing cranes are used mainly in Cement, Coal, and Fertilizer Handling Industries and to a extent steel manufacturing industry also.

Grabbing cranes are Motorized, 4 rope type synchronized with smooth hoisting, opening and closing of Buckets, which helps in achieving High Productivity. Grabbing Crane designed as per customer requirements only. Grabbing Crane for heavy and coarse materials, grabs are the most efficient solution. Grab Buckets are in operation for handling coarse materials like stones, Ferro-alloys, pig iron, DRI and HBI.

Grab Crane are special grabs with a very wide opening and large footprint which is extremely efficient during cleaning-up operations. Because the shells have a "horizontal closing path" the bulk material is "scraped together", instead of taking a bite out of the material. This makes it possible to ensure a good filling of the grab without having to penetrate the material. A special application for trimming grabs are dredging operations. The horizontal closing path makes it possible to work in layers and create an even surface.

Grabbing Crane is a very fast & operates at high speed for moving the materials. Our cranes are specially designed use & efficient working to give maximum output. These cranes are used for discharging bulk materials from ships, barges and more and are made from premium quality raw material. Available in different capacities and can be customized according to the client's requirements.We supply wide range of grab cranes, material handling crane, material lifting cranes, industrial material lifting cranes, industrial material handling crane, bulk material handling grabbing crane, grabbing cranes etc. Grab Bucket opening/closing mechanism is provided. Grab Buckets are specially designed for harsh use & efficient working to give maximum output. We can proudly claim to be manufacturing one of the Best Equipment in the country in India.

Capacity : Up to 25 MT

Span : Up to 40 mtrs.

Grab bucket capacity : Up to 6.Cu.M

Material handled : Mill Scale, Chemicals, Coal, Waste

Class of duty : Upto Class IV (M8), Extra Heavy Duty

Design Standard : IS : 3177 / IS : 807

- Class IV, ExtraHeavy Duty Grabbing Cranes with four rope type Grab Bucket for Chemical & Fertilizer industry.

- Scale Pit Cranes with Single Rope & four rope Grab Bucket for the Steel Industry

- Misc. application like coal handling, waste handling.

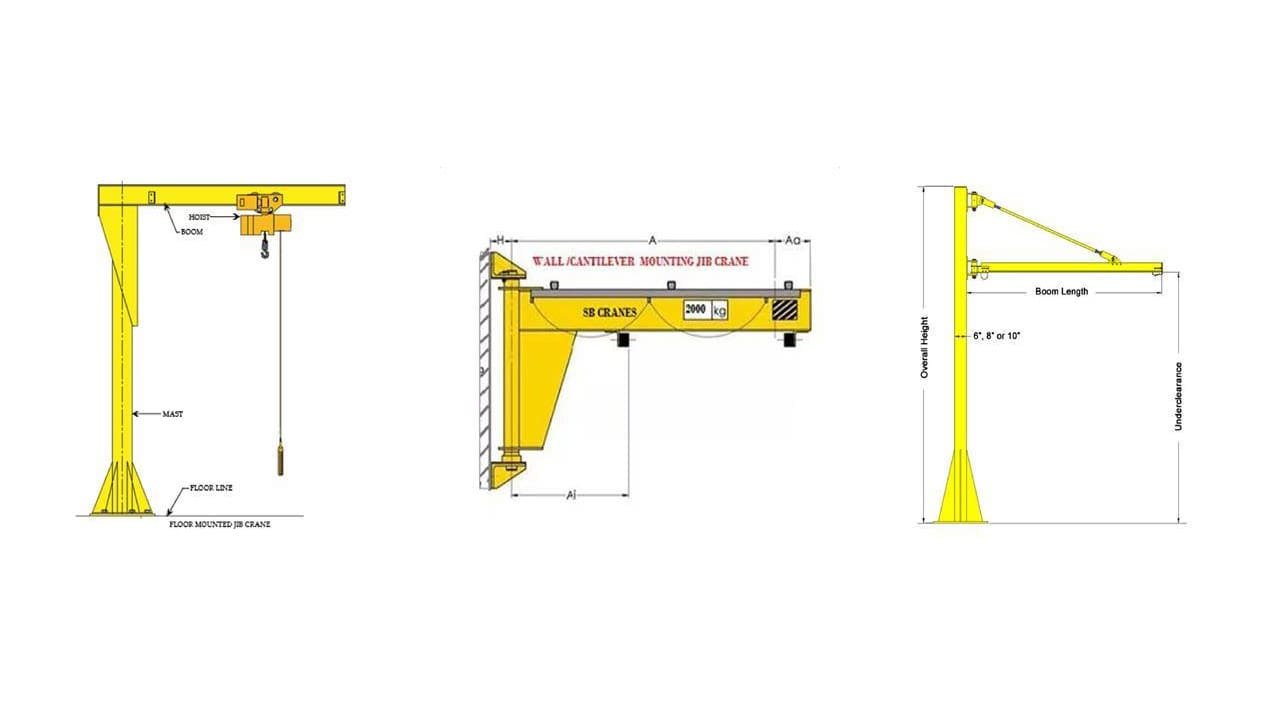

Jib Crane

Jib Cranes consist of a horizontal load supporting boom, which is attached to a pivoting vertical column that is either free standing or building mounted. They enable lifting and lowering of a load within a fixed arc of rotation. Jib Cranes can be provided in a variety of capacities and configurations including motorized rotation. Below are the basic types of Jib Cranes. Contact our Customer Service Department to determine the type of Jib Crane best suited for your application and facility.

Jib cranes are versatile efficient solution for moving material within an individual work station, for transferring materials from work area to work area for serving as auxiliary lifting devices under overhead cranes.

WALL MOUNTED TYPES

(Tension Bracket Jib Crane)

- Capacity from 250 kgs. To 3000 kgs.

- Span Up to 6 mtrs.

- 180 degree rotation.

- Utilized astd. l-beam.

- Most economical style.

- Allow max. usage of the area.

FULL CANTILEVER JIB CRANE

- Capacity from 250 kgs. To 3000 kgs.

- Span Up to 6 mtrs.

- 180 degree rotation.

- Offers greatest potential under boom clearance because it can be installed closer to the ceiling than other wall mounted jib cranes.

- Allow max. usage of the work area

SUPPORTED PILLAR

- Capacity from 250 kgs. To 5000 kgs.

- Std. Span Up to 5 mtrs.

- 360 degree rotation.

- Designed plants assembly is secured by mean of anchor bolts to prescribed reinforced concrete foundation with the number of anchor bolts varying with the capacity of the crane.

- The pipe column is designed to give max. strength and min. defection to resist bending, buelsling and crushing.

- The top bearing assembly utilities tapered roller bearing, provided with grease fitting for proper lubriction.

FREE STANDING JIB CRANES

Free Standing Jib Cranes are engineered to stand by themselves on a concrete foundation without building support. They allow for 360o rotation and can be base plate mounted, foundation mounted, or sleeve insert mounted. Standard capacities are from 1/2 to 5 tons. Special orders are possible up to 15 tons.

MAST TYPE JIB CRANES

Mast Type Jib Cranes offer a low cost alternative to achieve 360o rotation without a large mounting foundation as is required by free standing models. The mast is supported top and bottom by the overhead building steel and floor. Mast Type Jib Cranes are available in 2 designs, full cantilever and drop cantilever. Standard capacities are from 1/2 to 5 tons. Special capacities, heights and spans are also possible.

WALL MOUNTED JIB CRANES

Wall Mounted Jib Cranes are capable of 200o rotation. Their design can be either cantilever or tie rod supported. Wall Mounted Jib Cranes offer an economical alternative to Mast or Free Standing jibs, and with capacities standard up to 5 tons. Special capacities and longer spans are also possible.

Goods Lifts / Cage Hoists

Manufactured in capacities ranging from 0.5 tons to 7.5 tons with normally cage size of 3 mtrs. x 3 mtrs. x 3 mtrs. with or without collapsible gate with required lift and upto ground + 10 floor.

Goods Lift / Cage Lift are guided in steel guide member (T-section) with hoisting and lowering operations performed by our electric wire rope hoist. Operation is through interlocked push buttons and limit switches are provided for safety.

- LIMIT SWITCHES To prevent over hoisting & over lowering of hook.

- Limit swtich at each floor and cage doors / floor doors to avoid any accidental casuality.

- SPRING BUFFERS on the floor of the lift well to cushion the cage.

C Hook (35 Ton) for Coil Lifting

| Material | Mild Steel |

| Capacity | 10 MT to 30 MT |

| Min Coil Width | 20 in to 24 in |

| Max Coil Width | 48 in to 72 in |

| Throat | 24 in to 26 in |

| Weight | 210 lbs to 1170 lbs |

By keeping track of present growths, we are presenting an extensive range of MS Coil Lifter. The presented products are specifically developed in tandem with set norms by employing quality-approved material along with the contemporary technology. Presented products are tested in terms of quality so as to deliver a perfect range.

Features:

- Rigid design

- Excellent performance

- High strength