Electric Wire Rope Hoists

About the Product

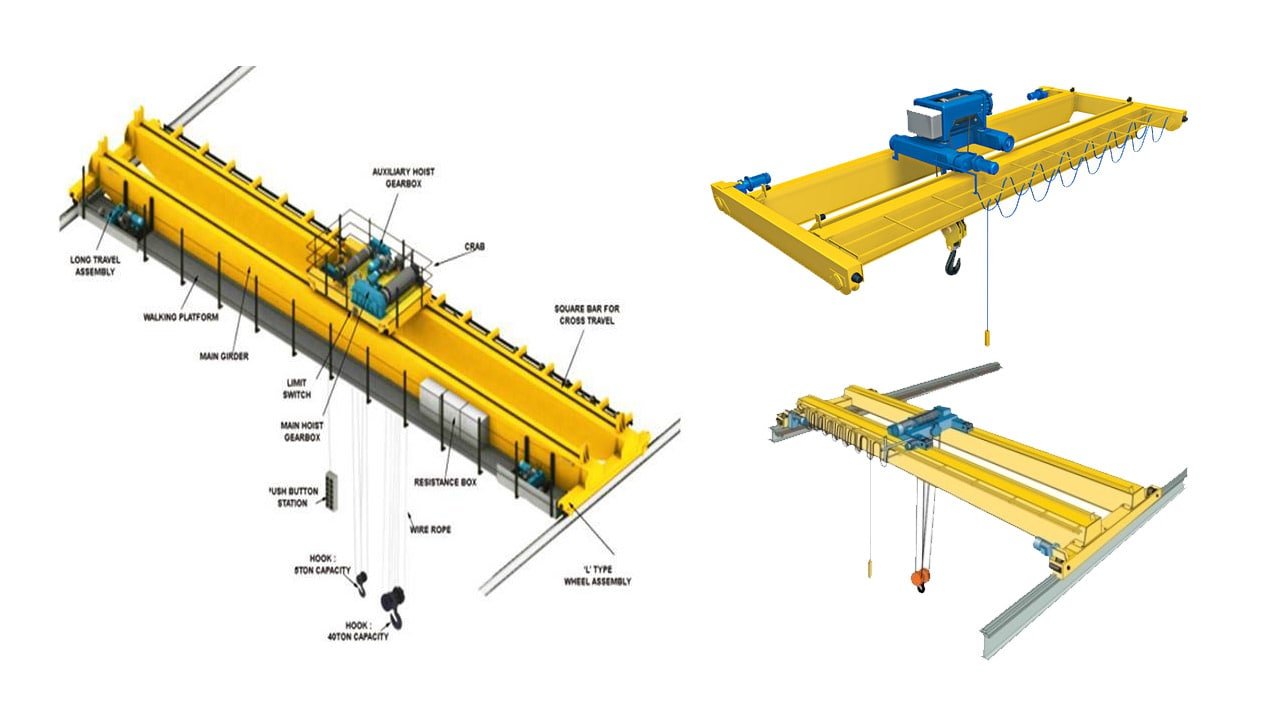

Wire Rope Hoists are designed & requirements of IS: 3938. Few salient features of the hoists are easy of use & maintenance, better Headroom, Modular construction.

| Features | Description |

|---|---|

| Rope Drum | Fabricated from Seamless Pipes with grooves for proper seating of wire rope. |

| Frame | Fabricated from plates confirming to IS: 2062, Gr A, laser cut profile & duly finished in boring machine. |

| Gears & Pinions | Helical type, made from Alloy steel materials, duly hardened and tempered. Teeth cutting carried out after heat-treatment for smooth, less noise operation. |

| Bearings | Heavy duty ball bearings of reputed makes used on all rotating parts, grease packed. |

| Motors | S4, 150 Starts per hour, 40% CDF, crane duty Squirrel Cage motors as per IS: 325 |

| Wire rope | As per IS: 2266 of reputed make suitable construction, factor of safety as recommended in IS: 3938. |

| Rope guide | Provided for guiding the rope along the axis of Rope slides & is easy to dismantle from rope drum. |

| Hook | Forged steel as per IS: 3815 supported on thrust bearing. Hooks as per IS: 15560 shall be offered on request. |

| Brakes | ACEM Disc brake provided for hoist and for Cross Traverse shall be provided on request. |

| Limit Switch | Normal roller type limit switch provided for over-hoisting & over-lowering. |

| Trolley Adjustment | Trolley easily adjustable for different beam sizes. Higher flange width shall be offered on request. |

PRODUCT DESCRIPTION

- CT Brake and CT Limit Switch

- Panel for LT Drive

- VFD for hoisting and cross traverse motion

- Higher height of lifts

- Different speeds for hoist and CT

- Power supply systems

- Shoe brake

- Manual geared trolley, flexible trol curvature, push-pull trolley

| S.W.L Kgs. |

Height of Lift in Mts. |

No. of Falls |

Speeds Mpm | Motor H.P | Flange Width of I Beam |

Wire Rope Dia |

Dimension(m.m.) | Approx WT. in Kgs. |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hoisting | CT | Hoisting | CT | A(HR) | B | C | D | H | I | ||||||

| 500 | 6 | 2 | 3.5 | 12 | 0.75 | 0.25 | 90-150 | 6 | 600 | 175 | 500 | 700 | 275 | 375 | 150 |

| 1000 | 6 | 2 | 3.5 | 12 | 1.5 | 0.50 | 90-150 | 8 | 650 | 175 | 500 | 850 | 275 | 375 | 170 |

| 2000 | 6 | 2 | 3.5 | 12 | 3.0 | 0.50 | 100-180 | 10 | 800 | 200 | 550 | 980 | 310 | 400 | 400 |

| 3000 | 6 | 2 | 3.5 | 12 | 5.0 | 0.50 | 125-180 | 10 | 850 | 225 | 600 | 1150 | 350 | 450 | 450 |

| 5000 | 6 | 2 | 3.5 | 12 | 5.0 | 0.50 | 140-400 | 10* | 1000 | 225 | 750 | 1250 | 450 | 450 | 550 |

| 7500 | 6 | 2 | 3.5 | 12 | 7.5 | 0.75 | 150-400 | 12* | 1200 | 225 | 850 | 1700 | 525 | 500 | 1000 |

| 10000 | 6 | 2 | 3.5 | 12 | 10 | 0.75 | 150-400 | 14* | 1300 | 225 | 850 | 1700 | 525 | 500 | 1200 |

| 15000 | 6 | 2 | 2.5 | 12 | 12.5 | 1.0 | 180-400 | 14* | 1600 | 300 | 1250 | 1850 | 650 | 600 | 1600 |

| 20000 | 6 | 2 | 2.5 | 12 | 15 | 1.0 | 180-400 | 18 | 1800 | 325 | 1250 | 1850 | 650 | 600 | 2200 |

Company Location

Why choose Modular Crane ?

- Well-qualified and experienced Team Members.

- Industry tie-ups and International collaborations.

- 10+ Years of Experience.

- High Standard Quality Materials

- Best Designed Structures

- Lifetime Support of Structures